Thorough Examination: the interactive guides

Stacker Truck Guide

Beware: not every Examination is truly "Thorough". CFTS is a national standard guaranteed to fulfil your obligations under LOLER 98 and PUWER 98.

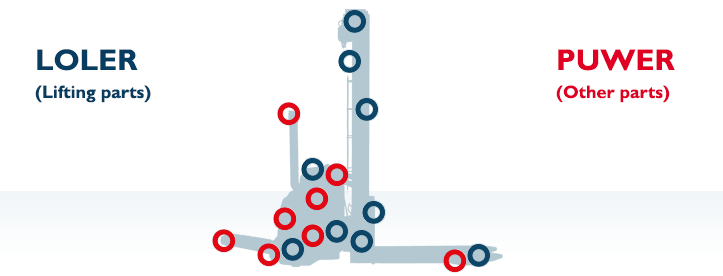

Some so-called "Thorough" Examinations only cover a fork truck's lifting mechanism, doing the minimum to meet LOLER 98 (in blue, below); but you also have a duty under PUWER 98 to ensure equipment is safe to use - and that requires a much more detailed examination (also including the items in red). A CFTS Thorough Examination is certain to cover both parts.

Hover your mouse over any section of the truck below to see which regulation covers that particular section of the vehicle. For example, would you want to use a truck that hadn't had its brakes checked?

Platform (if present)

The operator platform and side arms must be securely mounted and correctly adjusted for driver comfort. A CFTS examiner will also check any associated safety operate correctly. *may not be checked in a non-CFTS examination*

Tyres

Tyres are essential for safe and efficient operation. They provide grip for movement and braking. CFTS-accredited Thorough Examinations are guaranteed to check the tyres are correctly specified and fitted, and free from excessive wear, damage, or bonding issues. *may not be checked in a non-CFTS examination*

Brakes

Brake failure is a fork lift truck operator's worst nightmare, but brakes are left unchecked in many inspections. A CFTS examination includes a full brake test – checking all hydraulics, pneumatics, mountings, pedals, levers and linkages to ensure the brakes operate exactly as expected. *may not be checked in a non-CFTS examination*

Chassis

The chassis is inspected for cracking and signs of damage, paying particular attention to the welds. *may not be checked in a non-CFTS examination*

Steering

To ensure the truck can be operated safely, all mechanical and hydraulic steering parts are inspected for signs of failure, corrosion, damage or excessive wear. Proper steering response is confirmed by manoeuvring the truck at low speed. *may not be checked in a non-CFTS examination*

Traction System

The drive motor and gearbox must be checked to ensure smooth and progressive acceleration/deceleration. CFTS accredited companies also check that the truck can drive at slow and creep speeds. *may not be checked in a non-CFTS examination*

Battery

A CFTS accredited examiner will check the battery is correctly fitted and secure. This is more crucial if there is a battery exchange system fitted. *may not be non-CFTS examination*

Satety Systems

Safety systems can only protect workers if they operate correctly. Moreover, because operators come to depend on them, any failure can instantly cause serious unsafe practices. Any audible alarms and visible warnings are checked, along with interlocks if present. Capacity and data plates must also be present, secure and easy to read. *may not be checked in a non-CFTS examination*

Wheels

Because of the forces involved, wheel failure not only causes accidents: it can be a fatal hazard. A CFTS Thorough Examination ensures wheels and assemblies are sound and securely fixed. Bearings are given special attention. *may not be checked in anon-CFTS examination*

Rating Plate

Clear rating information is absolutely critical to the safe operation of any fork lift truck. The plate must be clear, securely attached, and updated to take account of any attachments fitted.

Controls

As well as the controls themselves, which must all be fully functional, securely mounted and clearly marked, all linkages and cables must be inspected to prevent potential failure through damage, corrosion or wear.

Hydraulic Systems

The hydraulic check is a major task, covering all hoses, pipes, cylinders and reservoir, along with a prolonged load test to rule out unacceptable descent. Filters are also inspected for signs of debris.

Carriage

The fork arm carriage must be free from distortion and cracking, with smooth operation from the bearings. Any load rest extensions must be structurally sound and properly mounted.

Load Guard

The load guard must be structurally sound and securely mounted to prevent falling loads. A poorly fitted load guard can be a hazard in its own right.

Chains

Lift chain failure is potentially lethal, but the wear, elongation of corrosion that can cause it are gradual and tricky to spot. A change of just 2% is cause for concern. Chains must therefore be checked carefully, in at least three places, along with anchors and pulleys.

Mast

The mast must be inspected throughout its full range of extension and movement to ensure a smooth, safe operation and structural integrity

Attachments (if present)

Any attachment must operate smoothly and safely throughout the full range of its movement. It should be mounted securely, and free from damage, distortion and cracks.

Forks

Fork arms are subject to constant abrasion and stress, making them particularly vulnerable. They must be of the correct capacity, meet ISO 5057 for wear, and must not be cracked, deformed or damaged. Fork location and end stops are also checked.

Read more about CFTS here.